FEATURES

OF THE MES SOFTWARE.

A MES software is an industrial production management system. It is frequently interfaced with other company management software, such as ERP , warehouse management software, SCADA for interconnection with machines ( Industry 4.0 ).

What is a MES software for?

A MES software is used to organize and check the production line of a manufacturing company.

Is used to organize because it:

- Idicates to the workers the activities to be performed and the right priorities;

- assigns jobs to machines based on settings;

- optimizes manufacturing, grouping the production of common articles and semi-finished products.

Is used to check because it:

- monitors the activities of workers and machines;

- check the progress of customer orders and work stages;

- verifies the occurrence of any anomalies or blockages;

- counts the quantities produced and any waste;

- record quality controls;

- produces statistics with the acquired data and performance indicators (efficiency, OEE), Pareto diagrams, etc.

How does a MES software work?

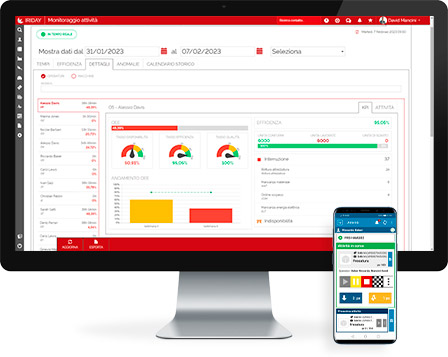

The best MES software provides the ability to exchange data in real time so to promptly resolve any critical production issues and timely update sales and customers on the eligibility of orders. Statistics, graphs and reports will be used by business analysts to evaluate performance and establish objectives and improvement plans.

Once the structure of an item to be produced has been defined, specifying the components and raw materials that compose it (bill of materials) and the necessary stages (work cycle), this can be used as a model for the real production.

As a result of a customer or internal order, a work order is “launched into production” which provides the use of the components envisaged in the BOM and the work cycle of the model article back into real production.

The workers, through the app, will be notified of the activities to be carried out, according to their duties and established priorities. They will record the activities in progress, indicating any quantities produced, waste, anomalies found, quality controls.

The MES software is designed for manufacturing companies, therefore it contains many functions expressly aimed at facilitating a company’s production process.

The correct question to ask is: do I need only a MES software or also an ERP?

An ERP software can help establish what production line needs, it can help manage inventory and this is certainly important to keep running costs under control in the long term. You can manage the part before production and the part after, that is to say when the item leaves the plant.

An MES software , as we said before, helps manage all production in real time. Thanks to the constant flow of data between enabled machines and production workers, it is possible to have a detailed picture of what is happening at that very moment.

Benefits of Iriday MES

Today, in the era of the transition to industry, a MES system is what we could define as a fundamental gear in a wider mechanism. In fact a Manufacturing Execution System ( MES ) is able to operate in synergy with an Enterprise Resource Planning ( ERP ) software to allow you to take on superior control over the company production model.

As a matter of fact, an ERP system has the role of:

- put all company departments in contact to share all the data useful for the business;

- integrated management of manufacturing process in collaboration with other software;

- production progress monitoring.

At this point it is clear how working in synergy with a MES software can increase the management potential for business activities, also being able to operate from an industry 4.0 perspective through IoT ( Internet of Things ) technologies .

And so what are the concrete benefits of a MES software?

- Analysis of the current state, as realistic as possible;

- Highlighting of critical issues, bottlenecks, recurring interruptions, production waste;

Precise time (and costs) calculation; - Creation of a historical models to accurately establish the “standard” processing times;

- Database for carrying out management control.

What is a MES software?

The production management software in the cloud, built on the field experience.

FAQ

-

What does the word MES mean?The acronym MES, Manufacturing Execution System, means a production management software, which allows you to organize work, collect production data, control machines, check progress and produce statistical analysis.

-

What does the word SAAS mean?The acronym SaaS, Software as a Service, means a model of software distribution, which does not require local installation because it is offered in the Cloud and, unlike the classic on-premise distributions, does not require an initial purchase cost, but provides a monthly fee based on the services used.

-

It is possible to have a local installation of Iriday Lythe?A traditional installation on a company server is possible but for costs, security, frequency of updates and speed of intervention, we do not recommend the "on premise" solution.

-

Is my data safe?Entrusting data to our systems is one of the best security system you can adopt. The Cloud system today is one of the safest places to store important information and sensitive data. We use all the most advanced tools to ensure maximum security and confidentiality of your data. Refining and testing them periodically. We provide automatic hourly backups of the main data and daily backups of the entire system, including disaster systems recovery.

-

How to choose a MES software?Try to identify the best MES software for your needs, evaluating the following points: 1. Ease of use: the interfaces for production operators must be simple, robust and intuitive. 2. Functional coverage: the best MES software provides modularity and configurability such as to often make writing custom code superfluous. 3. Data extraction and analysis: the best MES software offers a notification system that helps to be informed promptly, without having to periodically check boring printouts. 4. Flexibility and evolution over time: companies are alive, they evolve, grow, transform themselves… and the MES software must also follow these evolutions. 5. Integration with company software and connection of machines with Industry 4.0: the MES software is an indispensable support, an integrated system, with an automatic data flow that connects machines, MES system and ERP management software.

-

Can I have a demo of the software?They’re two trial modes: 1. You send us some of your data, such as: users, machines, bill of materials, work stages and related work cycles and we prepare, free of charge, a demo environment for you to be able to check the potential of the system. 2. To evaluate our way of working, you can ask us for a 6-month "full test", after a particularly low economic contribution. So that at the end of the trial period, you can decide whether or not to continue using the software.

-

How long does it take to start an MES project?The Cloud software is available immediately, but in order to fully exploit all its potential, it is advisable to plan a configuration and customization project which can last from 2 to 4 months, depending on the complexity. For "stand- alone" systems, or for systems that do not require interfacing, 2 months are enough. For more complex projects, which involve interfacing with other company software, such as ERP software or connection with machine tools according to the industry 4.0 standard, it can take up to 4 months.

-

What is the typical ROI of a MES project?Customers who have implemented the Iriday Lythe MES system have had a return on investment (ROI) between 12 and 18 months on average. The main benefits are: 1. Improvement of the OEE index, from 7% to 15% based on the industry sector. 2. Reduction of waste, from 3% to 8% based on the industry sector. 3. Reduction of items delivery times, from 5% to 9% based on the industry sector. 4. Reduction of customer complaints, from 6% to 11% based on the industry sector.

-

Is Iriday Lyhte MES software available for Apple IOS?The Iriday MES software consists of two workplaces:

1. Iriday Web application for system management and control, which can be used via browser and therefore from any device connected to the Internet: PC/Mac, tablet/iPad, smartphone/iPhone.

2. Lythe Android mobile app, for workers in production. Being a native Android app, it can only be used by Android devices (tablets, smartphones) or emulators. -

Is it possible to interface the Iriday MES software with other business software?Iriday Lythe MES software can be extended with other modules of Iriday family or interfaced with pre-existing business software, such as management software, attendance tracking systems, warehouse software and automatic warehouses.

-

It is possible to interface machine tools for "Industry 4.0"?Iriday Lythe MES system can be interfaced with the Iriday Industry 4.0 module to machine tools in compliance with Transition 4.0 requirements in order to obtain tax benefits. In this mode, the Iriday MES software communicates bidirectionally with the machines, exchanging the following data: production order/ stage to be processed, part program/recipe, machine on/ machine off, machine in process/ machine stopped, equipping phase/ removal phase, quantity produced, machine in block with failure causes.

-

Is it possible to interface out of date machine tools?Iriday IoT module can be used to interface the most obsolete machine tools or those which in any case do not provide for the methods envisaged in the "Industry 4.0" standards. In this mode, the system collects data such as: machine on/machine off, machine in progress/machine stopped, quantity produced, machine in block.

-

Can I import data from excel files?Import functions from Excel files are provided for the main system data, such as: customers, articles, bills of materials, work cycles, customer orders, production orders, warehouse stocks.

-

Can I export data to excel file?All system operating data can be exported to Excel file. You can load customized models in order to obtain the required information in the preferred way, or use the Excel sheets currently in use and link them to the data of the MES software.